Generally, upon delivery of an automatically detachable towbar, you should make a note of the key number. This can be found engraved in the key head, or as a five-digit number on the lock. You can request a new key from us at any time through your specialist workshop, using this key number.

If you have not made a note of the key number and there is only a three-digit number on the lock, then please request a universal key set from your specialist workshop. This contains all possible keys. In their own premises, your specialist workshop will then check which key fits and will send the complete key set back to us. Please then order the required key(s) separately through your repair shop or dealer by providing the selected number.

For retractable towbars, the ball head is always firmly attached to the crossbar. This system is equipped with a handwheel which must be operated in order for the ball head to fold down. Light pressure applied to the ball head will lock it into its final position. The handwheel is used to swing it out of the way, and the ball head is removed by gently lifting it out of the lock. Now, the ball head can be locked in place again under the vehicle.

The function of the flanged ball valve is similar to that of the ball rod of a towbar. In many cases, for a hitch block, this can be replaced by another flanged ball valve. If this is less than 49 mm it must be replaced.

We are also happy to send you a new type plate as soon as we have received a statutory declaration from a repair shop containing the identity of the towbar, amongst other details.

The Federal Motor Transport Authority a ruled that the direct delivery of type plates to the vehicle owner is unfortunately no longer permitted.

To simplify this process for you, you will find a statutory declaration for your repair shop below which you should then fill out and send via fax back to the mentioned numbers in the document (please note: different numbers for OE and aftermarket business).

As soon as we receive the completed form containing a legally binding signature, we will immediately dispatch the type plate to your repair shop. Find more information here.

For bicycle racks, we recommend a rigid or fully automated detachable towbar. These towbars are designed for heavy loads.

For a detachable towbar, you have the option to remove the ball head. In doing so, it should be noted that the ball head must always be removed when not in use. It is possible to distinguish 2 detachable systems. The hand and lever system on the one hand and the fully automated system on the other hand.

Indication of the vertical load of the towbar can be found on the type plate and in the assembly instructions, given in kg. Please note that the specifications of the vehicle manufacturer must be observed. These can be different!

A hitch block is a special type of towbar where there is no ball head fitted, but rather a flanged ball valve. For hitch blocks, different flanged ball valves can be used. For transporters, this type of towbars is recommended because the height on the trailer can be adjusted in the optimum way by using different flanged ball valves.

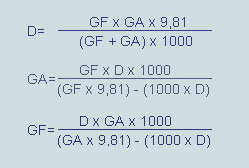

The D-value of a trailer coupling is the basis for calculating the acceptable towing capacity. Once defined and tested using a suitable design, it remains fixed.

The D-value is determined as follows:

D [kN], GA (towing capacity) [kg], GF (acceptable total weight)[kg]

For a vehicle with a fitted towbar and with damage to its rear, it is suspected that the towbar was also damaged through overloading. As a general rule, damage can be identified by permanent deformation. Other characteristics could be: Surface damage, any unnatural notches or displacements in the fastening area and, for towbars with a detachable ball-head suspension rod, also excessive backlash of the removable parts.

We examine towbars that are sent to us for inspection by inserting them into a specific test gauge. If this is not dimensionally stable, it can be assumed that damage has occurred due to overloading. Such trailer couplings must no longer be used.

Checking for dimensional accuracy alone does not provide information about possible cracks or the beginning of cracks which, during trailer operation over time, can result in complete equipment failure. Micro cracks can be overlooked when examining using the dye penetration process or ultrasound. However, in the majority of cases, the x-ray method does not seem economically viable. In cases of doubt, we generally recommend the replacement of such couplings, although the final decision does of course fall to the technical expert.

Disconnecting the ball rod is carried out by using a rotary control or a locking lever. By pulling it out or pressing down on it, the rotary control can be turned until it locks in place. Only then is it possible to remove the ball rod. When reattaching the ball rod, it is pressed into the slot using the wound rotary control until the rotary control jumps back and therefore locks in place.

If a vehicle is equipped with automatic level control, it consistently pumps itself back to the starting height during loading. This back pumping can commence straight after loading or after a short drive.

This is a low-priced version of the detachable towbar. For some vehicle models, an opening must be made in the bumper which cannot be concealed. Therefore the ball head slot is visible if the ball head is detached. You can refer to the towbar item details to find out whether this is the case for your vehicle.

A swap system represents the connection between the hitch block and the flanged ball valve or bar coupling. It is possible to attach the flanged ball valve and the bar coupling to a changing plate. This makes it very easy to switch between the flanged ball valve and bar coupling. The flanged ball valve and the bar coupling do not always have to be screwed on. It is possible to replace this with a changing system in a few simple steps.

A bar coupling plays a similar role to the ball rod or the flanged ball valve of a towbar or a hitch block. It is therefore the coupling point for trailers with coupling rings.

We are happy to clarify whether it is possible to use a bar coupling on your hitch block. In order to do this, we need the following details: manufacturer, manufacturer number and the mark of conformity of your hitch block.

The advantage of the fully automated system is that it is lockable and suitable for all types of trailers. In addition, the fully automated system stands out due to it being very easy to use and having an especially high load capacity and service life.

For all towbar which have already been tested according to European standards (mark of conformity begins with an “e”), TÜV approval is no longer necessary. It is sufficient if the towbar installation guide is carried in the vehicle. This serves as a general operating license.

For towbar with a German mark of conformity (M or F), it is necessary to have TÜV approval, as well as to immediately record the installation of the towbar in the vehicle documents.

The towbar with an individual approval (TP marks of conformity) posses a separately provided approval certificate for each tow coupling. After installation of the towbar, a TÜV approval is necessary, as well as making a record in the vehicle documents.

The ball rod, together with the ball head, is the part of the towbar which is necessary for retaining the trailer or goods trailer.

In this instance, we generally recommend a detachable or retractable towbar. When installing a fixed towbar, the ball head can extend into the sensors’ detection area, resulting in the parking assistance (PDC) constantly detecting an obstacle despite this being the ball head of the towbar.

This is the load that is allowed to act vertically on the ball head from above. The verticlal load is generally between 40 and 200 kg, depending on vehicle type. The vertical load of the towbar and the vehicle must not be exceeded.

The acceptable vertical load can be found in the vehicle manual. The vertical load of the towbar is noted on the type plate and in the installation guide.

The maximum vertical as specified by the vehicle manufacturer must not be exceeded.

The towing capacity is the load that the vehicle and the towbar are permitted to tow. The towing capacity of the vehicle is determined by the vehicle manufacturer. This is different depending on the type of the vehicle. The trailer loads permitted for your vehicle can be found in your vehicle documents, namely:

Old vehicle registration certificate

-

Trailing load with brakes under no. 28

-

Trailing load without brakes under no. 29

New vehicle registration certificate

-

Trailing load with brakes under O.1

-

Trailing load without brakes under O.2

The maximum permitted trailer load of the towbar is noted in the installation guide. It is determined by the towbar manufacturer. The towing capacity of the towbar can differ from the towing capacity of the vehicle. The value entered in the vehicle documents is always decisive! This weight must not be exceeded!

For fixed towbars, the ball head is firmly attached to the crossbar (screwed or welded together), and therefore always remains visible. Even if the ball head of the towbar is screwed in place, it must not be removed because this will cause the operating license of the vehicle to expire.